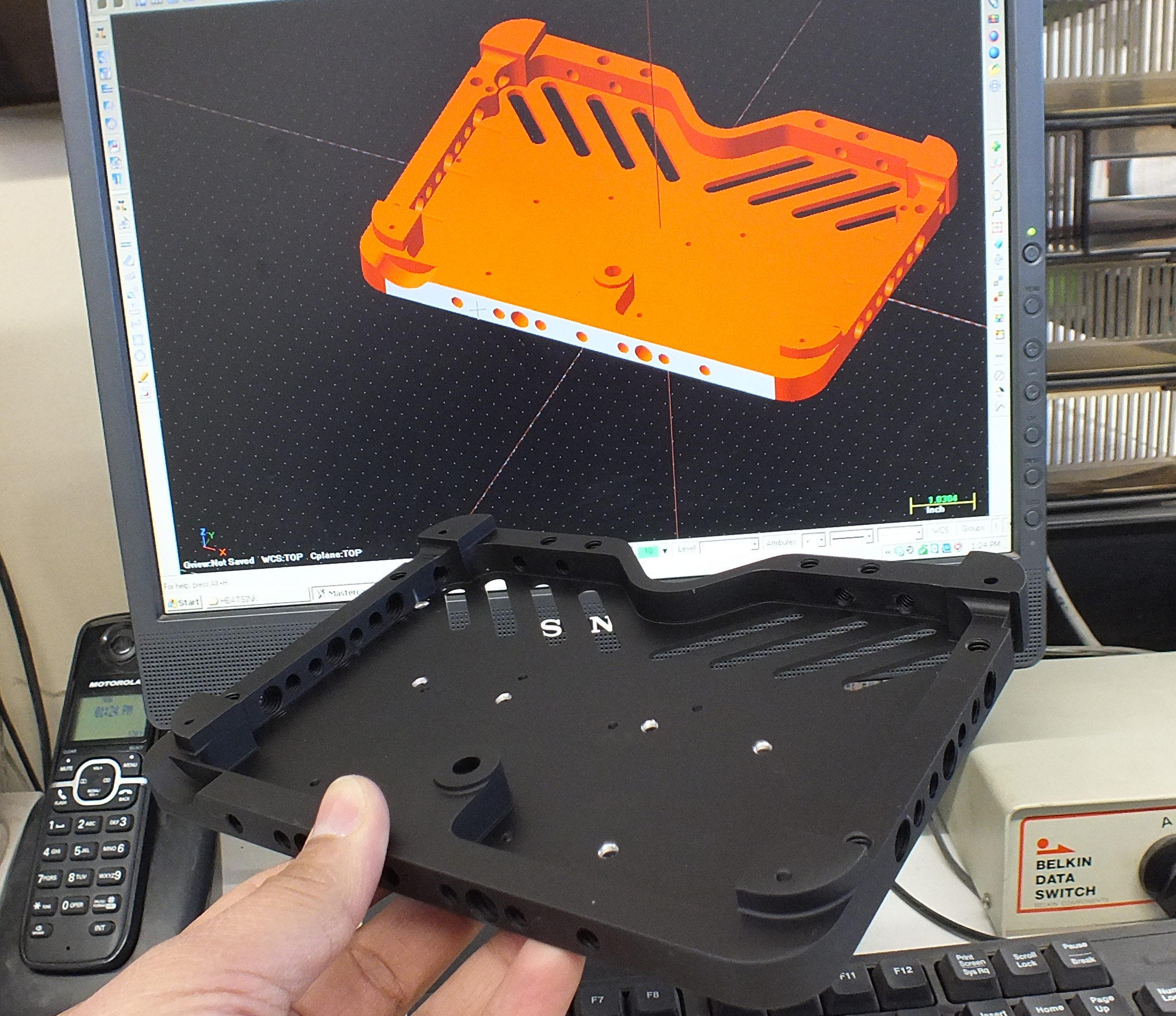

Machining after net blank shapes cut

This reduces overall production time by alot. Instead of machining a part out of a rectangle, the part can be machined from near net shape already cut with waterjet. We make our own custom machine-ready blanks with the waterjet. Big chunks of material is removed on the waterjet. This dramatically reduces the machining time. We achieve not only a cost savings for our customers, but a effecient way to go.

From CAD File or Print to Part

All our programming is done in-house, with our cad programming system. We can reverse engineer your part and make a new one. Most of the cadfiles received from our customers are either in .DXF, .DWG,.AI or IGES Format. Bring us your tamplet, we can match it. Most of our cnc machining jobs are in high production runs. We can take any tamplet, sketch or artwork and convert it into a vector file format.

Part Quality

We work under the ISO 9001:2008 and AS9100C quality control system. Before a job is shipped, it is inspected to ensure the requirements are met, and is in compliance with customer’s specifications. All the products will meet the customer’s purchase order applicable statutory and regulatory requirements. Certification of conformance is provided as required for each job. Quality is assured.