WATERJET

What is waterjet cutting ?

A needle sharp stream of high pressure abrasive water does the cutting. Cutting motion is computer controlled. Material, when cut, stays in it’s natural chemical composition. It’s a cutting method that doesn’t use harsh chemicals, produce any high heat, or cause toxic fumes. Waterjet cutting is environmentally friendly. The cut is clean and precise. Cutting is done with water and sand under high pressure.

ex: rubber, plastic or wood does not have burned edge from the cut. Metal cut edge is not heat effected.

Why Use Waterjet Cutting?

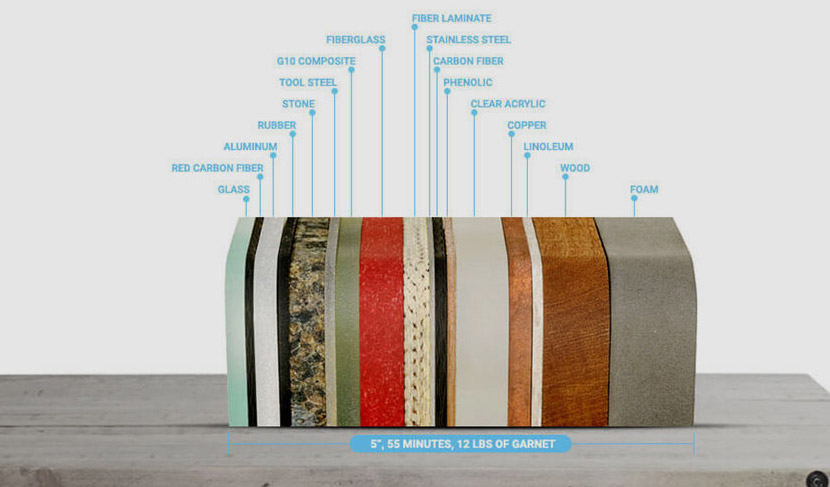

- No material cutting limitations. Can virtually cut any type of material.

- Cut net shape of part and then cnc machine it. Saves ton of machining time & tool cost.

- No heat, warping, or material discoloration.

- Capable of cutting complex & difficult shapes.

- Cut materials that lasers can not.

- Smooth finish with very little burr.

- Very cost effective way to go.

- No costly dies or fixtures required.

- Easily cut materials as soft as foam or hard as rock.

- No thermal stress put on material. Excellent for aerospace materials.

- Cleaner cutting alternative to plasma cutting and flame cutting.

- Time reduction compare to other cutting methods. Materials can be stacked and cut.

- Can cut materials as thick as 12 inches.

- Faster parts turn-around.

We can pretty much cut any type of flat material !